In today’s fast-paced industrial world, efficient warehouse management is crucial. Our cutting-edge automation and semi-automation systems are designed to streamline your operations, reduce costs, save space and enhance productivity.

Automated Storage and Retrieval Systems (AS/RS or ASRS) consist of a variety of computer-controlled systems for automating the storage and retrieval of loads from defined storage locations.

An AS/RS is typically used in applications where:

Our AS/RS solutions increase efficiency and accuracy while reducing operational costs. Ideal for high-volume and space-constrained environments, AS/RS systems enhance productivity by providing agile and error-free service.

A VLM is an enclosed system with two columns of trays and an inserter/extractor in the centre. The VLM optimizes storage density by automatically adjusting tray heights within the system to use the least amount of space required.

This AS/RS application increases throughput, reduces labour costs, and maximises warehouse floor space, making it a strategic addition to modern warehouses.

The Radio Pallet Shuttle is a semi-automated storage and retrieval system that uses an electric shuttle to load and unload pallets from racking.

The storage and retrieval of pallets are easily managed by remote control: a pallet is loaded onto the shuttle and orders are executed to load or unload pallets into a lane. The forklift operator instructs the radio shuttle on whether to store or retrieve the pallet. The first location on the racking system is for the forklift to release the pallets, which can be a FIFO (First in First out) or FILO (First in Last out)

This compact storage solution allows for maximum use of warehouse space and increases productivity by optimising throughput, ensuring faster and more efficient pallet handling.

The 4-Way Shuttle is a high-density pallet storage system that uses multi-directional shuttles. The shuttle can automatically switch 90 degrees in the longitudinal storage and the transverse transfer channel. The machines are connected via a wireless network. This system maximises warehouse capacity, productivity, and flexibility. The WMS Management System allows for FIFO (First in First out) or FILO (First in Last out)

This is an ideal solution for warehouse storage with a complex terrain environment.

The 4-Way Shuttle increases storage capacity, reduces labour costs, and offers exceptional versatility for handling dynamic warehouse demands.

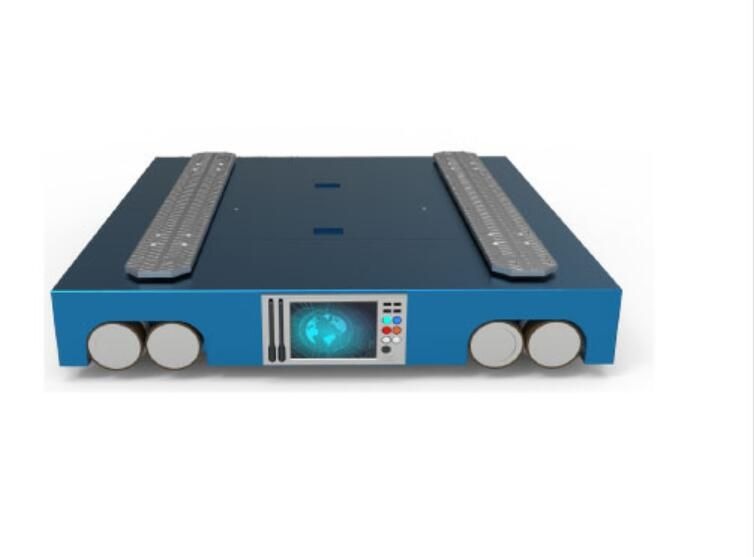

AGVs are driverless robots that transport goods within a warehouse. They either follow along marked lines or wires on the floor, or use radio waves, vision cameras, magnets or lasers for navigation.

Often used to transport heavy materials around a large industrial building, our AGVs take over repetitive transport tasks, ensuring optimal process stability and reducing error and accident rates. They automate the flow of goods, allowing for 24-hour operations and freeing up employees for higher-value tasks.

This means continuous, efficient, and safe transport of materials within your warehouse.

Movirack is a high-density mobile racking system that optimises space and increases storage capacity. Mounted on motorized bases, the racks move laterally to open the required working aisle, providing seamless access to stored goods. This system combines high-density storage with direct access to each pallet.

This is an ideal solution for warehouse storage with a complex terrain environment.

The 4-Way Shuttle increases storage capacity, reduces labour costs, and offers exceptional versatility for handling dynamic warehouse demands.

We improve warehouse efficiency through advanced warehouse automation/semi-automation systems and smart industrial racking & shelving solutions

© 2025 All Rights Reserved.